Technical Data

We have several types of processing machines and a full range of evaluation equipment at our plant.

We can customise our products to fit your specifications.

Please refer to our technical data by clicking the following link.

Diamond properties

Mechanical properties

Expansion into ultra-precision polishing

Market requirements

1. Higher Precision

Finished surface is grain size dependent

2. Alternatives to CMP

High speed and ultra-mirror surface requirement

Limitations of chemical reactions

Technical Challenges

1. Atomisation

Precise classification technology

Dispersibility (coarsening due to agglomeration)

Handling properties

2. Abrasive Properties

Reduction of micro-cracks

3. High Purity

Refining technology

Sliding characteristics

Characteristics required for sliding materials

→Same features with ultrafine-grained diamonds

1. Wear Resistance

Hardness dependency (diamond = No. 1)

2. Low Friction Coefficient

Ultrafine-grained diamond μ < 0.1

3. High Durability

(Maximum PV, High Elastic Modulus)

4. Affinity with Other Materials

Not suitable for Fe-based materials

5. Corrosion Resistance

Diamond = chemically stable

Challenges: Coating, mass production, processing etc.

Thermal and Electrical Properties

Properties required for heat sink materials.

- 1. Thermal Conductivity = High

- 2. Thermal Expansion Coefficient = Low

- 3. Dielectric Constant = Low

- 4. Insulation (Specific Resistance) = High

- 5. Stability of Properties

- 6. Adhesion = Good

Challenges: Difficult formability, mass production, cost competitiveness, etc.

| Thermal Conductivity [W/m-K]. |

Linear Expansion Coefficien [x10-6/K]. |

Specific Resistance [Ω-cm]. |

Dielectric Constant [1MHz]. |

Dielectric Strength [kV/mm]. |

|

|---|---|---|---|---|---|

| Diamond | 2000 | 2.3 | 1016 | 5.6 | 350 |

| Al2O3 | 20 | 8.0 | >1014 | 9.2 | 14 |

| SiC | 60-490 | 4.2 | <106 | 4.4 | 400 |

| AlN | 70-260 | 4.7 | >1014 | 8.7 | 15 |

| BeO | 250 | 7.8 | >1014 | 6.5 | 10 |

| Silicon Si | 150 | 2.6 | - | 11.8 | 30 |

| Silver Ag | 430 | 19.1 | 1.6x10-6 | - | - |

| Copper Cu | 400 | 16.8 | 1.7x10-6 | - | - |

Excellent properties as semiconductor

material Diamond substrate

↑Seed crystal for crystal growth

- 1. high band gap and thermal conductivity → High temperature compatibility

- 2. High mobility and dielectric strength → High speed and power compatibility

- 3. High saturation velocity and dielectric breakdown voltage → High frequency compatibility

- 4. Low dielectric constant → High speed compatibility

| Lattice constant [Å] |

BandGap [eV] |

Mobility[cm2/V-s] | Saturation Electron Velocity [cm/s] |

Dielectric Breakdown Voltage [kV/mm] |

||

|---|---|---|---|---|---|---|

| (Electron) | (Hole) | |||||

| Diamond | 3.57 | 5.47 | 1800 | 1600 | 2.5x107 | >350 |

| 3C-SiC | 4.36 | 2.23 | 1000 | 700 | 2.7x107 | 400 |

| 6H-SiC | 3.09 | 2.93 | 500 | - | 2.0x107 | 250 |

| Silicon Si | 5.43 | 1.12 | 1500 | 600 | 1.0x107 | 30 |

| GaAs | 5.65 | 1.43 | 8000 | 400 | 2.0x107 | 40 |

| GaN | 3.19 | 3.39 | 900 | - | 2.7x107 | 40 |

| ZnSe | 5.67 | 2.67 | - | - | - | - |

Other properties.

- 1.Toughness 7.5 (equivalent to quartz)

- 2.Optical properties Single refractive index, refractive index 2.417, dispersion 0.044, transparency

- 3.X-ray transparency available

- 4.Excellent chemical resistance

- 5.Acoustic material properties / Specific elastic modulus:325[1010dyne/g/cm]

Propagation velocity:18,000 [m/sec]. - 6.Catalyst Carrier

(e.g.) 2-PA decomposition activity (300 °C)

Confirmation that surface treatment by calcination and acid treatment results in a highly active acidic catalyst

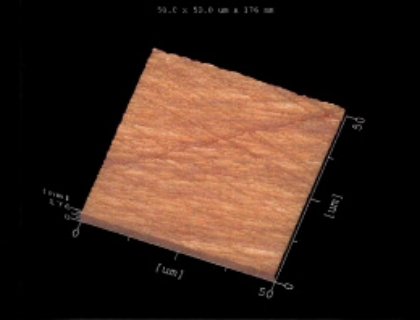

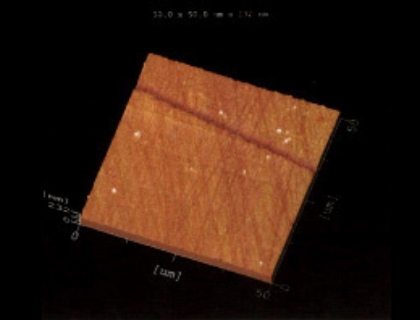

Sapphire Glasses

One example of sapphire polishing

Polishing Condition

Gvaluation Result

DIAMOND

Diamond

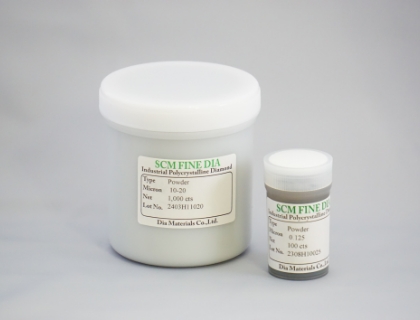

SCM FINE DIAMOND

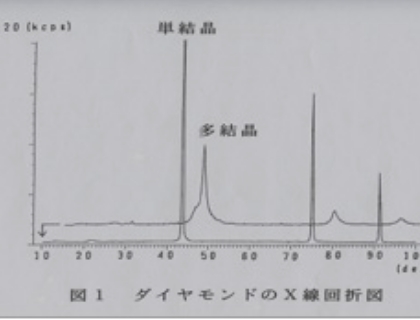

Mono-Crystalline Diamond

Other Materials

Our polycrystalline diamond powder product “SCM FINE DIAMOND” shows extremely high performance in precision polishing of ceramics and other hard materials, compared with the monocrystalline diamond powder which has been widely used in the past.

Digital technology is developing by the day and the importance of precise polishing for ceramics and other hard materials is increasing more than ever. Our SCM FINE DIAMOND is now becoming vital for the tech industry.

難加工材の研磨速度の一例

Diamond

DIAMOND