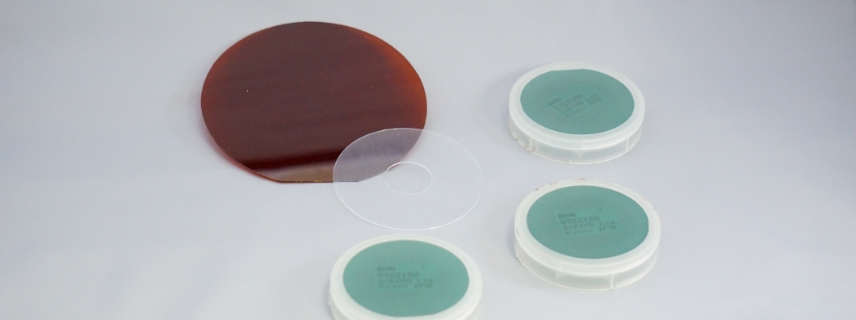

SCM Nano Diamond

About SCM Nano Diamonds

Dia Material develops diamond particles with an average particle size of less than 100 nm (0.1 µ) as ultrafine (nano) diamonds.

As a domestic manufacturer, we pursue a stable supply of nanodiamonds while actively conducting joint research with various industries to develop new applications.

| Types of nano-diamonds (ultrafine diamonds) handled (origin of production method) |

|

| Polycrystalline (impact compression) |

Monocrystalline (static pressure) |

Diamond Properties

Hardness, low friction, high thermal conductivity, low thermal expansion, wide gap, stability, surface properties, etc.

Application development

Ultra-precision polishing, solid-state sliding, plating, heat sinks, CVD seed crystals, electron emission, UV blocking, catalysis, adsorption, medical, etc.

Physical properties of nanodiamonds

Polycrystalline type

100nm, FE-SEM x100,000 times

100nm, TEM x80,000 times

Secondary particles can be classified in 50 nm intervals

Residual impurities inside the sintered body (<1%)

Monocrystalline type

100nm, FE-SEM x100,000 times

100nm, TEM x80,000 times

(Static pressure method, 50,000 atmospheres, 1,200°C x approx. 10 min)

X-ray diffraction chart of nanodiamonds

Various diamonds (grain size 100 nm) Powder X-ray diffraction results

| Polycrystalline | Monocrystalline | UDD type |

|---|---|---|

| CUB/HEX | CUB | CUB |

| FWHM1.2-1.8 | FWHM0.4-0.6 | FWHM1.7-2.2 |

| Particle size 10-20nm | - | Particle size 3-8nm |

Polycrystalline

Monocrystalline

Examples of Raman spectroscopy

measurements of nanodiamonds

Crystallinity (1330 cm-1): single crystal > UDD type > polycrystalline

In cluster diamonds, a non-diamond carbon peak (sp2 carbon) is often identified around 1580 cm-1.

Polycrystalline type

Monocrystalline type

Handling of

nanodiamonds: classification

Polycrystalline type

100nm d50=0.0991μ, mv=0.1065μ, s.d. 0.0385

80nm d50=0.0828μ, mv=0.0874μ, s.d. 0.0338

50nm d50=0.0505μ, mv=0.0562μ, s.d. 0.023

Products for conventional applications are available in the abrasives market.

Samples are available for other applications and for sub 50nm applications.

Tested by MicrotracUPA

Monocrystalline type

100nm d50=0.1028μ, mv=0.1041μ, s.d. 0.0344

80nm d50=0.0815μ, mv=0.0852μ, s.d. 0.0244

50nm d50=0.0536μ, mv=0.0589μ, s.d. 0.0246

Products for conventional applications are available in the abrasives market.

Samples are available for other applications and for sub 50nm applications.

Tested by MicrotracUPA