SCM Fine Diamond

About SCM Fine Diamond

The demand for ceramics, which are both hard and heat resistant, is growing rapidly. Polishing and grinding of these ceramics requires greater efficiency and precision than ever before. Various products using our polycrystalline SCM FINE DIAMONDs have excellent polishing and grinding capabilities for precision machining.

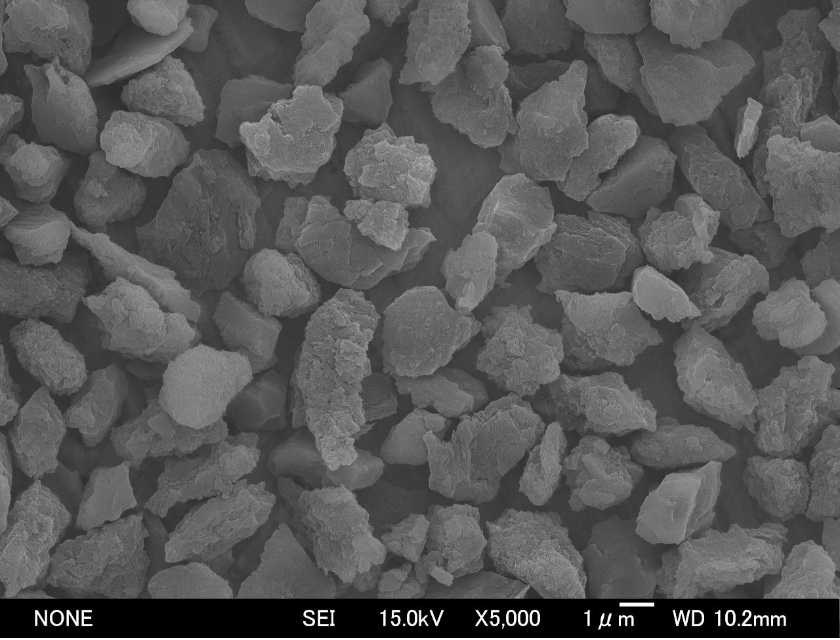

Polycrystalline structure of microdiamond crystallites forming random secondary aggregates

SCM fine diamonds with blocky geometry

Characteristics

The industrial diamond powder is classified in terms of synthesis and structure as shown in the table below.

Synthetic monocrystalline diamond, which accounts for more than 90% of industrial diamond powder, is produced by static synthesis method.

It's particle has the sharp edges, and it is widely used for diamond wheel, blade, cutter and so on.

On the other hand, SCM FINE DIAMONDs are polycrystalline type, which are synthesised by the shock compression method under our highly controlled technology.

One particle of the diamond by this method is composed of the numberless fine primary diamonds which are strongly concentrated with each other having the blocky shape.

-

Mono-Crystalline Type

More Scratch & Lower Removal Rate

- Few Sharp Edges

- Cleavage Plane

- Angular Shape

-

Poly-Crystalline Type

Less Scratch & Higher Removal Rate

- Numberless Fine Edges

- No Cleavage Plane

- Blocky Shape

Production of SCM FINE DIAMONDs

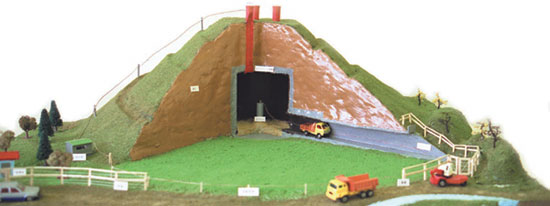

Polycrystalline diamonds are synthesised by explosion and we operate an artificial explosion dome in Akabira, Hokkaido.

This facility is proud to be one of the largest diamond synthesis domes using explosions.

We actively participate in explosion and synthesis testing at the request of industry, academia and government.

Our Explosion Facility for Diamond Synthesis

Production Process

After the explosive synthesis process, there is a refining process to remove impurities, a milling process to adjust shape and size, a grading process to sort the size range with high precision, and an inspection process based on strict in-house standards.